1999 Yale Forklift

Details

- Purchase date: April 13, 2020

- Purchase Price: $2500

- Model Year 1999

- Fuel Type: LP

- Truck Model No: GLC040AFNUAV061

- Lifting Capacity 4000lb

- Collapsed mast height: 82″

- Weight 6840lb

- Side Shift

- Drive Tread Width: 34″

- Back Tilt: 5deg

- Drive Tire Size/Type: 18x7x12-1/8/Solid Rubber

- Steer Tire Size/Type: 15x5x11-1/4/Solid Rubber

- Engine: Mazda FE 2.0L 4 cyl

- Fuel Capacity 7.5Gallons

Background

The building has high ceilings with the second floor level over 14′. There is a good amount of vertical space for storage downstairs and a long way to lift heavy items up to the second floor. The Lull works great for outside work but it’s too big to be of much use inside. I started looking for a forklift in late 2019 and ended up finding this one on craigslist. The guy said he bought it at an auction in Des Moines, put a new battery and gas bottle but he couldn’t get it running. I noticed a DRA lot number on the vertical support column and was able to find the auction site which supported the sellers story and gave me confidence he was being honest. He turned out to be a great guy.

DRA Auction Site: (not sure how long this link will stay up)

https://auctionresource.com/auctions/3378/online-only-equipment-auction/386064/yale-forklift-dr4447-unit-5584

The seller was in Battle Creek, Iowa which is about 2 hours away from Louisville. I hitched the F350 up with the new trailer and the wife and I went for an afternoon outing. Below picture shows the seller loading it with his large loader and me unloading it with the Lull.

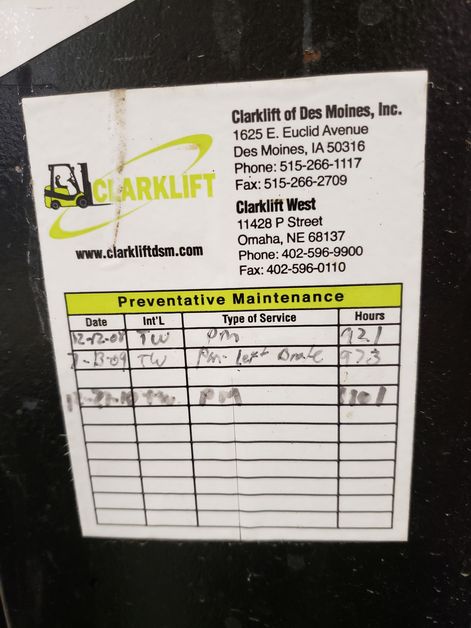

For a 20+ year old machine it looked to be in great shape. the rubber on the pedals isn’t worn, the paint is in great condition and it just looked relatively unused. The hour meter was a little past 1100 hours which the seller said wasn’t likely accurate and I agreed with him at first. There was a maintenance sticker on the boom that showed it was serviced in 2010 at 1101 hours. The machine was covered in bird shit which told me it was stored in a barn for some amount of time. From all outward appearances it looked like this machine was put away in 2010 and never used again… but why?

The way home started off fine until we decided to take a shortcut through some very hilly Iowa backroads. The F350 started to over heat and boiled over. I had enough coolant and water in the truck to get it going again but it quickly overheated again a few miles away. I stopped at a couple farms on the road and filled up my water jugs and limped the truck to Onawa Iowa. I found an Oreilly’s and installed a new thermostat and stocked up on coolant and water. The rest of the drive home was relatively uneventful but the issue was far from fixed. More on that on the F350 page.

Fix it, Fix it, Fix it

Now that I had it home I wanted to hear it run. there was a LP solenoid unplugged and after I connected that and gave the engine a little starting fluid it fired right up. The hydraulics seemed to work but it wouldn’t drive. The engine sounded a little rough and there was pulley somewhere with a bad bearing.

Transmission

After adding fluid it worked however it was leaking fluid at an alarming rate. To my dismay it appeared the transmission housing was cracked. It looked like someone tried to lift it with another forklift and it snapped. Looking underneath it was clear someone lazily smeared some JB weld on the oozing wound but of course it did nothing. This does however explain why it’s in such good shape and makes me think the hours may be accurate. The auction site confirmed it came from a large company in Des Moines, IA as the seller stated. I imagine two guys messing around trying to lift each other and they cracked the transmission. The company put it away to be fixed later but it got buried and forgotten. I have no idea what a transmission would cost and given the situation I decided to try and fix it myself first.

Ben’s redneck transmission fixer guide:

- Drain the fluid

- Apply vacuum to filler

- Grind out the crack for filler weld

- Weld, grind, weld, grind

- Cover with sealant

Even after draining there was a small amount of transmission fluid that kept coming out of the crack. Welds don’t tend to stick to oil so I had to figure how to stop it from leaking without tearing it apart. I ended up connecting a vacuum cleaner on the fill tube to create negative pressure. I then cleaned the crack with solvent and waited to see if it leaked, it did not. Before Left, after Right.

The case is cast iron so I used nickel wire for my mig welder. After I was done welding and while the metal was still hot with the vacuum running I applied a generous amount of my favorite sealant PL. The idea was the PL would be softened by the heat and if there were any holes it would get pulled in by the vacuum. I turned the vacuum off after it cooled and left the PL to cure for about a week. PL is amazing stuff but it takes a while to cure.

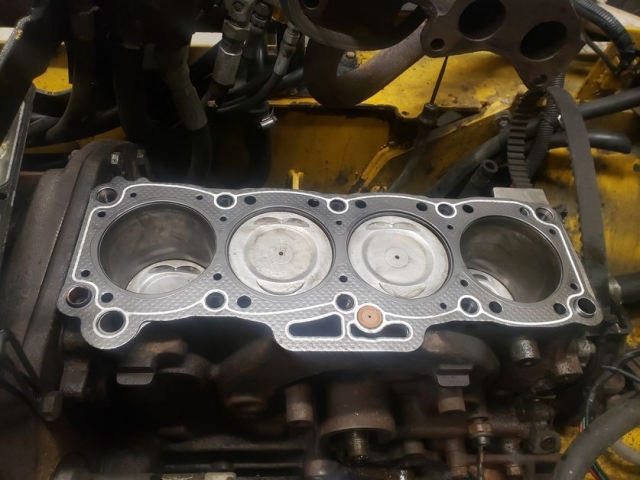

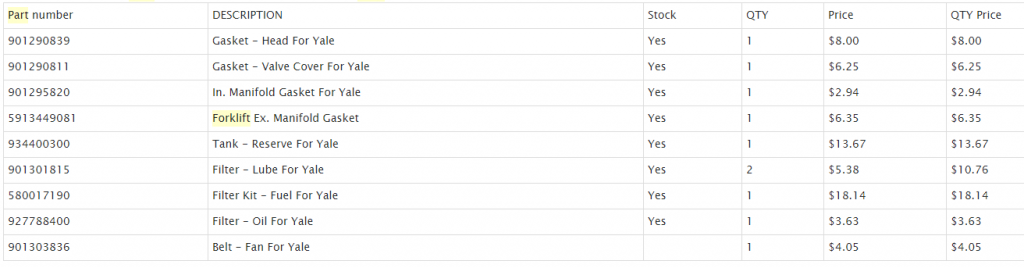

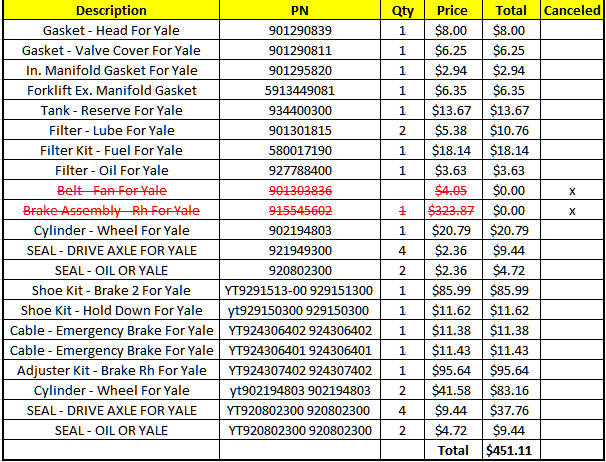

This appears to be a very common model and I found several parts websites but I preferred to use https://www.liftpartswarehouse.com/. Most parts are surprisingly inexpensive ($8 for a head gasket) and they had nearly everything in stock. The only thing you have to watch out for is they will hold an entire order if one part is out of stock. If they don’t ship it within a day or two contact them to see what’s holding it up. For the order below it was the V-belt which I could get at Napa so I had them remove it and ship the remaining items. The right front wheel was leaking gear oil which in turn ruined the brake pads. Machines don’t like to sit for a long period of time and most rubber seals and gaskets needed to be replaced. I ended up purchasing a complete brake drum repair kit for both sides, seals, filters, hoses, master cylinder, brake fluid reservoir and even new boots for the hydraulic control levers. There was some trial and error but after 3 or for 4 orders I had everything. Parts order example below:

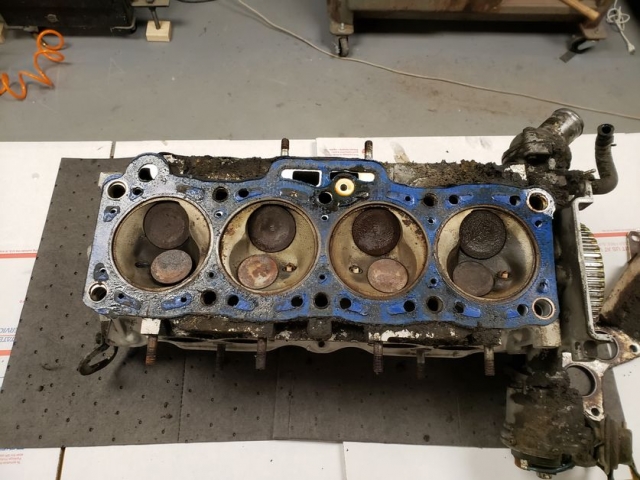

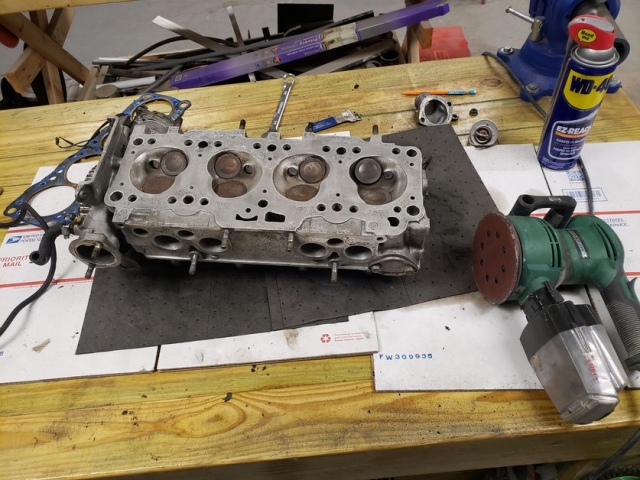

As I gained experience with this machine I started to worry the head gasket was bad. I took this opportunity to perform a full tune up and replace anything that that looked like it needed it along the way. I prefer to tear new toys apart so this step felt very natural to me.

Brakes

I don’t know what it is with me and brakes. After replacing the seals on the left side it still leaked and it turned out the shaft sleeve was pitted. The right side didn’t seem bad but I decided to completely replace both sides and go through the entire brake system. I rebuilt both brake drum assemblies, replaced both emergency brake cables, master cylinder and fluid reservoir.

Parts from Lift Warehouse.com.

It Works

First engine test after repairs. This makes it all worth while…

It took 1 month from the time I bought it to when I had it all put back together and running. Most of this time was waiting for parts or sealant to dry. The Lull was instrumental in lifting it on and off the jack stands. It’s the size of a lawn mower but it weights more than a 3/4″ ton truck.

Of course no project is complete without the wife giving it a test drive.

Test Drive!

It’s unnecessarily fast for a forklift with a top speed of ~14MPH. It pushes the limits of the steering linkage but it’s a lot of fun to drive full speed honking the horn and flashing the lights. Most of the safety’s were disabled when I got it otherwise all the electronics work. I replaced the head lights with LED and replaced the right rear light bar cover which was cracked.

Front tilt cylinder blow out

I hauled the forklift to Omaha to pickup a large CNC table. Loading was uneventful until I went to load it back on the trailer. One feature of this model is it has very little ground clearance and only likes to run on flat concrete. In order to get it on the trailer I had to take a run at it and the impact when it went up the ramp was sharp and I noticed a huge amount of oil was pouring out. At first I thought it was the transmission and my crack repair had failed but after getting parked on the trailer I realized it was hydraulic fluid. For whatever reason both front tilt cylinders blew their front and wiper seals when the forklift impacted the trailer. I tore both cylinders down and replaced all the seals and it was back to working order.

As of March 2021 this was the last major issue it had and it’s been working well.