New Holland L250

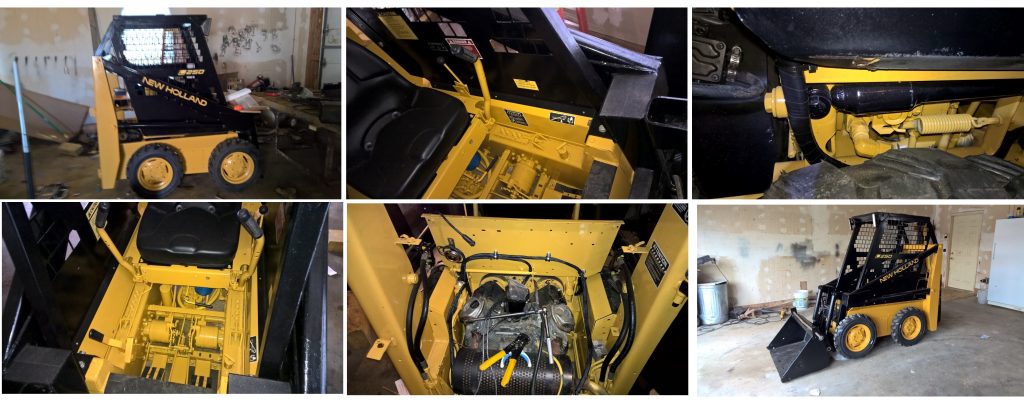

This is my little 1994 New Holland L250 I call “The skidloader”. It’s a 36″ wide model designed to fit through standard door frames and gates. It’s perfect for life in a town or situations where space is tight.

With the stock configuration the bucket is small and the machine is back heavy so it can’t dig and has generally poor performance all the way around. The hydraulics are relatively slow along with the wheel speed so without an effective front loader this machine isn’t all that great. The addition of a bucket extender and counter weight make all the difference. The rated load capacities are very conservative and likely rated for safe operation rather than mechanical limits. I’ve had the bucket load well over 1000lbs many times and it has no trouble at all.

Fun fact. This is the same model used in Diehard 3

Bucket volume ~432in^3. Gold has a density of 11.17oz/cubic in. 432/11.17 =4825oz = ~300lb. If you ever wondered if it could lift a bucket full of gold the answer is yes.

Origins of this machine

My dad discovered the value of these little machines long ago and has had several over the year. He was the first to make a bucket extender to fully realize the potential and one had been floating around for years he made for another model that was long gone. He bought this one from an old lady who’s husband died and kept it in a garage. It was in pristine condition but it wasn’t long before it was on it’s second engine and deteriorating fast. My dad replaced the stock wheels and tires with car tires with the idea it would be easier on grass and give the machine a little more ground clearance. It did indeed do these things however the extra rubber made it very bouncy and the overall width was now too large to fit through standard gates. I started using it when I bought my first house in 2014 which is when I fell in love with it. I don’t have many before pictures but what I could dig up are below.

Restoration

During the spring of 2015 we took the opportunity to restore the machine. Dad put a new Honda 20HP engine in it not long before but it was in need of repairs and maintenance plus I wanted to do my thing to it and install some custom electronics. The first step was to tear the machine apart. Dad perfected the art of rolling and brushing on implement paint which I thought was crazy until I saw how good the finished looked and how strong it was on his other projects.

I really didn’t care for the car tires and I wanted to restore the original tire size so it could again fit through small areas. I found the original wheels and purchased new 8 ply tires from Firth Nebraska for about $100 each mounted. Lots of surplus center parts, new wheel seals, belts, filters, fluid change, etc. I also found the original decals and purchased a kit online.

I planned to make a new custom bucket extender but I needed to make a rear counter weight before finishing the rear door. I made wood form and welded some metal reinforcement then poured it full of concrete. It’s pretty banged up now and if I make it again I will add a metal frame around the edge to protect the concrete from cracking when backing into things.

New Bucket Extender

The old bucket extender was made by dad years ago for another model. It fit poorly and was very difficult to install and remove.

I wanted the new bucket extender to be made of a heavier gauge steel and more rigid but allow for it to be easily removed. I went with 10awg cold rolled steel and used 4.00X 0.25″ gussets with 0.125″ structured angles. I found some 0.5″ spring bolts online and used an old hardened steel implement blade dad had at the farm for a tooth bar. Originally the tooth bar was smooth but I later cut teeth in it to improve digging. The build process was essentially to mark the pattern out then use the plasma cutter to cut a “dotted line” then bend on the line. Once bent I welded in the supports.

The original flat tooth bar was a piece of hardened steel from a farm implement. The flat bar was terrible for digging and after a while I used my plasma cutter to add some teeth. Like most buckets there isn’t much point in painting it as it doesn’t take long for the paint to wear off.

Use and Abuse

The most traumatic event happened when I was digging a dead tree out of the front yard. For some reason I backed the skid loader into a hole I just dug and tipped it over.

I caught myself on the security camera. When it happened it felt like it happened really slow. It surprised me how fast it was after watching the video.

Molly recorded me tipping it back up right.

General Use and Abuse Gallery

Electronics

It wouldn’t be one of my projects without custom electronics. After renting some modern equipment I really liked the idea of a keypad VS keys so I went with a membrane keypad and DogM LCD transmissive character display.

The purpose of the controller is to automate some of the systems and make it easier to operate.

Features:

- Waterproof and cold resistant

- LCD display readout with system info

- Membrane keypad for passcode access and control

- Digital system monitoring and automatic shutdown for overheat, cooling fans, oil pressure, battery voltage warnings and tipover sensor

- ESP8266 for webcontrol (System monitoring, Autostart, etc)

- Independently controlled front and rear LED lights

Inputs/Outputs:

- Inputs:

- Selt Belt

- Engine Tachometer

- Engine Temperature

- Hydraulic reservoir Temperature

- Battery Voltage

- Fuel Level

- Oil Pressure

- Ambient Air Temperature

- Tilt Sensor

- Outputs:

- Front Lights

- Rear Lights

- Boom Solenoid

- Choke

- Horn

- Cooling Fans

- Starter

- Engine Enable/Disable

- Power Control

- Aux 0

- Aux 1

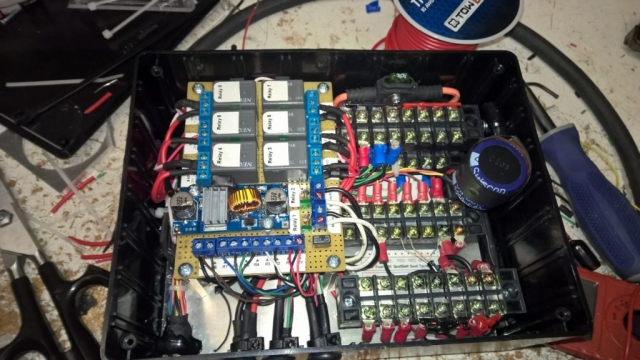

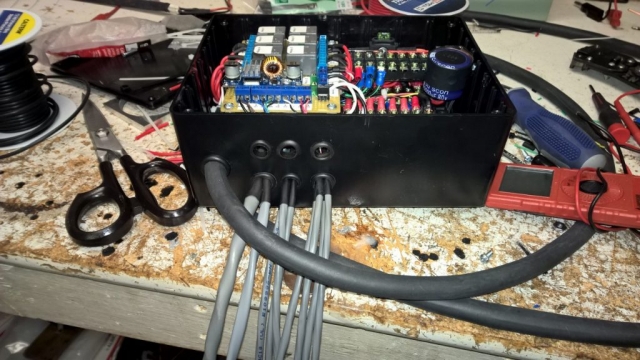

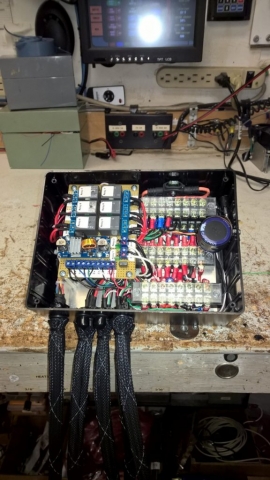

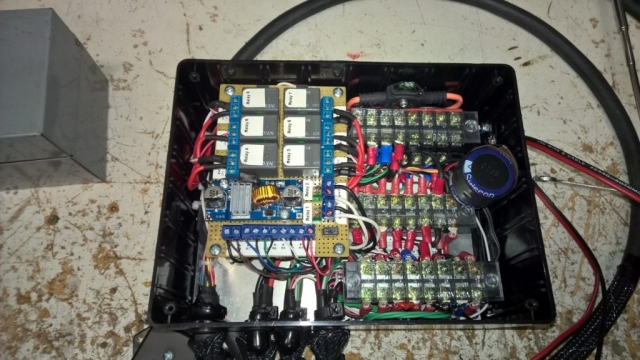

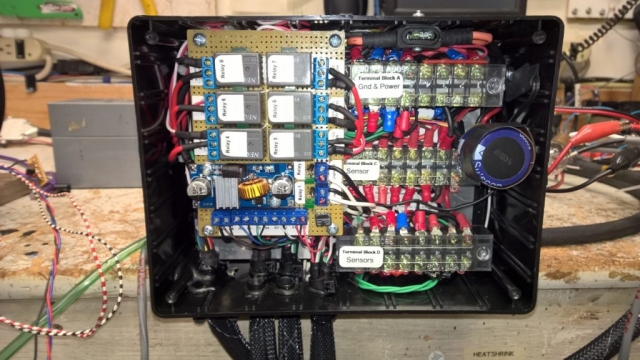

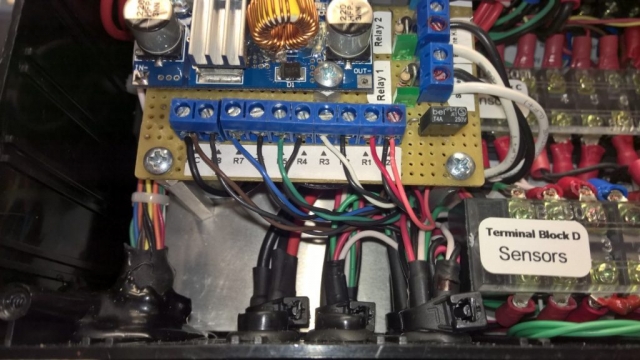

Controller pictures

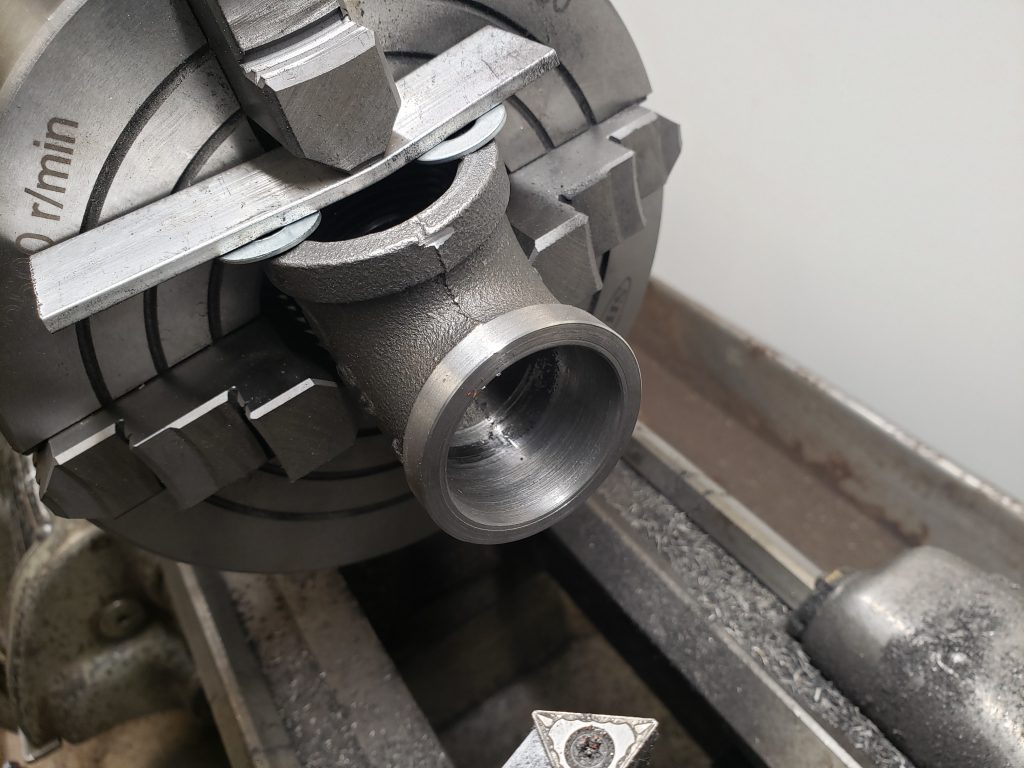

The roundish device is an alternator off a Kubota diesel engine from a Snapper lawn mower. I added a photo interrupter for RPM sensing which is what’s shown on the back.

Fuel Level Sensor

The idea was to have a pressure sensor read the fuel level by extrapolating it from the pressure taken from the bottom of the tank. I’ve used this method before for water level sensing and it works great however in this situation I failed to consider the dynamic environment. The level will read properly when the engine is off and at rest but as soon as it become disturbed the fuel start to shake and vibrate and the readings are all over the place. I tried doing some simple averaging and filtering but it didn’t do much. This is on my list of things to address. One reason it hasn’t been too high on my list is this machine has a serious design flaw where they put the fuel tank directly above the muffler. The muffler heats the fuel and when the tank gets too low it starts to boil and the engine will shut off. I added the cooling fans which helps but the right solution would be to move the exhaust or fuel tank but there isn’t really a good place to move it. I’ve decided to wait and address this the next time the engine needs to be replaced.

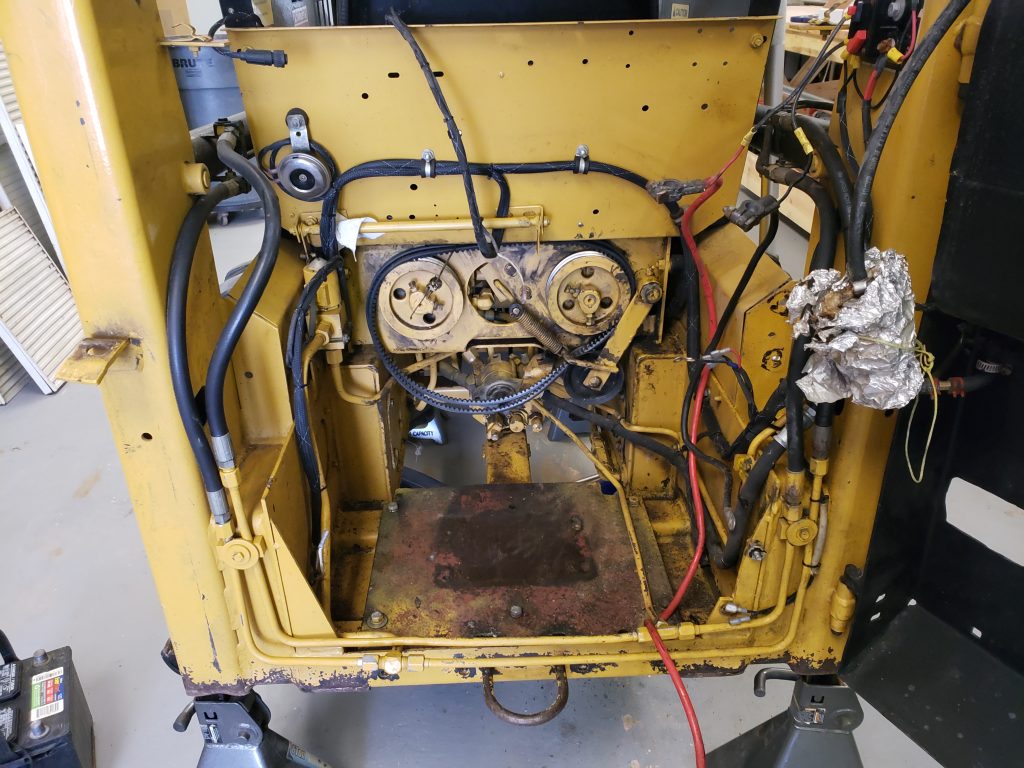

Replaced Engine July 2019

The old Honda engine was a beast but it was over heating constantly, burning a ton of oil and losing power. After some research I decided to go with a Harbor Freight 22HP Predator engine. I picked one up with a coupon for under $700 so it ended up being about half the price of a Honda. The conversion gave me an opportunity to fix some lingering issues such as increasing cooling and a new pump shaft adapter.

The muffler was unfortunately taller than the old one so I had to make an adapter to plumb the exhaust down and out of the back door. I added some heat insulation to the bottom of the gas can to help with issue of the gas boiling especially when the fuel get’s low. I also added a high CFM pusher fan and reversed the existing top fans to increase air flow. The fan requires 15A which exceeds the generator on the Predator engine so I put the old alternator back on and dedicated that to drive the large fan. The new engine has an oil cooler on the side and it seems to stay much cooler than the old engine. If overheating becomes an issue in the future I’m thinking of getting an external oil cooler from Surplus Center and mounting it to the back door but so far it hasn’t been an issue.